细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

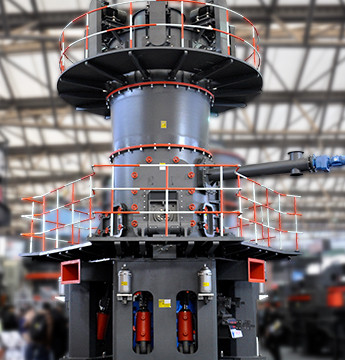

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Crusher Media Charge Calculation In Finish Cement Ball Mill

.jpg)

Computation of charging media for a double compartment

2024年1月26日 Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time2018年7月24日 Ball charges: This calculator gives the surface and the average weight of the ball charges It gives also a rough interpretation of the ball charge efficiency: Ball charges calculators thecementgrindingoffice2024年1月27日 To investigate the effects of grinding media shapes on the grinding kinetics of ball mill cement clinker, the grinding effects with ϕ20 mm balls and ϕ20 × 20 mm cylinders on Computation of charging media for a double compartment cement ball mill 2021年3月12日 Ball mills and grinding tools Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the BALL MILLS Ball mill optimisation Holzinger Consulting

.jpg)

ball mill calculations, grinding media filling degree, ball size, mill

online live calculators for grinding calculations, Ball mill, tube mill, critical speed, Degree of filling balls, Arm of gravity, mill net and gross powerOptimization of a ball charge for cement and raw mills with objective of optimizing the grinding efficiency The ball charge in first and particularly in the second compartment, will be adapted Ball charge optimization INFINITY FOR CEMENT EQUIPMENTSemantic Scholar extracted view of "Computation of charging media for a double compartment cement ball mill" by Harish Kumar et putation of charging media for a double compartment cement ball mill 2015年2月9日 Mills 3 Ball charges Composition Calculator for 3 Chambers Mills 4 Modification of the Ball Charge after Sampling Analysis Calculator 5 Calculation of the Top Size Grinding Training Courses based on the Grinding Software

.jpg)

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

2013年3月13日 Empty heights of both the chambers measured to calculate the ball charge, % filling and estimate the power consumption at mill shaft Based on the empty height 2004年12月10日 Beside the mill inside diameter D and the L/D ratio the porosity of the ball charge ɛ, the true density of the grinding media ρ k, the ball charge filling ratio φ k and an Optimization of continuous ball mills used for finishgrinding Ball mills for finish grinding cement usually consist of two compartments An intermediate diaphragm separates both compartments from each other Ball Charge Ball mills for cement grinding usually operate with a filling degree Process Training Ball Mill INFINITY FOR Coal mining processing plant in Nigeria This coal mining project is an open pit mine located in Nigeria, announced by mining company Western Goldfields that it has discovered 62,400,000 tonnes of proven reserves of coal deposits worth US$12 billion which could be used for the generation of electric powergrinding media charge calculation in cement ball mills

(PDF) Grinding Media in Ball MillsA Review

2023年4月23日 A comparison of the grinding media is given together with the knowledge gaps that still need to be bridged to improve the quality and performance of grinding media used in ball mills2024年1月26日 Grinding media is mostly prepared from high chrome steel Ball mills are efficiently utilized for final grinding of clinker It grounds the raw mix (clinker) into fine powder Ball mills are available of different sizes and capacities Ball mill may be of two compartment or three compartments The schematic view of cement ball mill is shown in Computation of charging media for a double compartment cement ball mill 2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum GrindingPrevious Post Next Post Contents1 Ball charge optimization2 1 How to use the BP21 2 Description of the main indicators used in this BP2101 The residue on 2mm/4mm before partition wall2102 Material filling level and ball charge expansion211 Cement mill specific power 1st compartment 212 Raw mill specific power 1st compartment Ball charge Ball charge optimization INFINITY FOR CEMENT EQUIPMENT

.jpg)

Training Courses based on the Grinding Software

2015年2月9日 Monochamber Mills 2 Ball charges Composition Calculator for 2 Chambers Mills 3 Ball charges Composition Calculator for 3 Chambers Mills 4 Modification of the Ball Charge after Sampling Analysis Calculator 5 Calculation of the Top Size Grinding Media 6 Ball Charges analysis calculator Weight and Surface of the Grinding Charges 7 Ball 2016年10月5日 1 Introduction Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent years, the production EnergyEfficient Technologies in Cement GrindingCement Ball Mill Grinding Media wildcer cement ball mill grinding media – Grinding Mill China cement ball mill grinding media composition Request for feedback for a Two Chamber Cement Mill Ball Charge and Jun 15, 2011 I am looking to get feedback for the following cement mill for a white cementgrinding media ratio in cement mill KOOKS2021年11月9日 Mar 16, 2017 cement mill ball mill all calculation cement boll mill grinding media calculation,cement finish grinding mill ball mir shabbir ahmad apr 29 2013 here is the method for correct calculation of cement mill ball charge step 1 draw the cross section of cement ball mill separator efficiency calculation,dynamic air separator cement ball mill grinding media chargingHXJQ Crusher

how to measure a cement finish mill ball charge Sebocom

2013/04/29 Cement mill ball charge calculation Grinding of cement accounts around 40 % Electricity bill at a Cement Plant For economic efficient operation of a cement mill correct quantity, size and size range of grinding media plays a vital and pivotal roleGrinding Cylpebs For Ball Mill Grinding cylpebs is a type of grinding media with a short cylindrical or truncated conical shape Just like the grinding ball, it can also be divided into the metallic type and nonmetallic typeIn largesized industrial Ball Mill Grinding Media – Grinding Media Balls ball mill critical speed formula – iron ore crusher, gold ore Through ball mill critical speed formula, CEMENT MILL FORMULAS MILL CRITICAL VELOCITY = 76 / (D)^1/2 MILL L ball 7, critical speed calculation; Velocity Calculation In Ball Mills Crusher Mills2004年12月1日 During the last decade, semifinishgrinding plants have been used more and more for the energy efficient grinding of highquality cement In 1999, it was found that by decreasing the ball charge Optimization of continuous ball mills used for finishgrinding

.jpg)

Everything you need to know about clinker/cement Grinding

For raw mills it is most common to use a ball charge with the coarse grading (up to 50% of 90 mm balls) – see table below for “coarse” grading Cement Mill The ball charge tendency in the 1 st compartment is to use the coarser of the gradings available When producing high Blaine Cement it is the objective to use less tonnage Achieve The present work is aimed at further understanding of the design studies of feed chute for powdery feed material and truck using FEM and DEM software and to use in the further designs of ball mills 11 FLS UMS Type Cement Ball Mill In 1893 FLSmidth (FLS) firm acquired the rights to a new mill type, the tube mill, from the French/Danish inventorDESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER PRESS CIRCUIT 2013年3月13日 The mill is designed to handle a total ball charge of 3245 t at 100% loading with a percentage filling of 295% in both the chambers Both the chambers of the cement mill were charged with 80% of the designed charge,PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits According to the need of customers, ball mill can be either wet or dry designs Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameter Applicationgrind media distribution calculation for ball mills

.jpg)

Computation of charging media for a double compartment cement ball mill

2024年1月27日 To investigate the effects of grinding media shapes on the grinding kinetics of ball mill cement clinker, the grinding effects with ϕ20 mm balls and ϕ20 × 20 mm cylinders on six different size 2022年5月10日 BallmillFinish Mill Ball Charge Calculation Free download as Excel Spreadsheet (xls), PDF File (pdf), Text File (txt) or read online for free This document contains data from a ball mill operation including percentages of material at various sizes over time, dimensions of the mill chamber, average piece weight, specific surface area, and a graphBall Mill Finish Mill Ball Charge Calculation PDFCement ball mill is a cement grinding machine used in the cement production line for cement clinker grinding AGICO supplies the cement ball mills for processing limestone, cement clinker, gypsum, slag, ore, etc Largest ball charge(t) Cement Ball Mill Cement Grinding Machine2017年4月29日 But the proper size of the balls can be determined only by a careful study of the existing conditions Experimental data must here be resorted to and the following method is recommended as a good means for determining the exact size of the balls that should be used Charge the mill with large balls, say of 5in (127 mm) diameterGrinding Media Wear Rate Calculation in Ball Mill

calculation in filling ratio for ball mill KOOKS

TECHNICAL NOTES 8 GRINDING R P King Mineral Tech Figure 85 Effect of mill filling on power draft for ball mills The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure 842024年7月7日 Ball Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals evaluation Methods for assessing ball charge, wear rates, and liner Ball Mill Grinding Process Handbook PDF Mill (Grinding)2024年1月5日 Ball mills are tube mills used for grinding materials like cement and involve several components The document discusses the movement of grinding media in ball mills, optimal ball charge and filling levels, key components like linings, diaphragms, drives and bearings, and factors that influence mill operation such as ventilation, water injection and Cement ball mill process calculation pdf PPT SlideShare2019年8月30日 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and Ball Mill Parameter Selection Calculation JXSC

.jpg)

Formula to calculate grinding media wear rate for cement mill

2024年10月13日 How to calculate grinding media wear rate In order to calculate the grinding media wear rate for a cement mill, we first need to understand the wear mechanism The wear of grinding media in a mill is a complex phenomenon and can be influenced by a number of variables Some of these variables include:The type of mill (eg, ball mill, rod mill Ball mills, internal installations and grinding media charges – Calculation of power consumption for ball mills and grinding media charges – Automatic process control for Ball Mill Calculations Critical Speed – Raymond Grinding MillBall Mill Calculation Crusher Mills, Cone Crusher, Jaw CrushersAn inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just thatBall mill for cement grinding FLSmidth CementBall mills for finish grinding cement usually consist of two compartments An intermediate diaphragm separates both compartments from each other Ball Charge Ball mills for cement grinding usually operate with a filling degree Process Training Ball Mill INFINITY FOR

grinding media charge calculation in cement ball mills

Coal mining processing plant in Nigeria This coal mining project is an open pit mine located in Nigeria, announced by mining company Western Goldfields that it has discovered 62,400,000 tonnes of proven reserves of coal deposits worth US$12 billion which could be used for the generation of electric power2023年4月23日 A comparison of the grinding media is given together with the knowledge gaps that still need to be bridged to improve the quality and performance of grinding media used in ball mills(PDF) Grinding Media in Ball MillsA Review2024年1月26日 Grinding media is mostly prepared from high chrome steel Ball mills are efficiently utilized for final grinding of clinker It grounds the raw mix (clinker) into fine powder Ball mills are available of different sizes and capacities Ball mill may be of two compartment or three compartments The schematic view of cement ball mill is shown in Computation of charging media for a double compartment cement ball mill 2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding

Ball charge optimization INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 Ball charge optimization2 1 How to use the BP21 2 Description of the main indicators used in this BP2101 The residue on 2mm/4mm before partition wall2102 Material filling level and ball charge expansion211 Cement mill specific power 1st compartment 212 Raw mill specific power 1st compartment Ball charge 2015年2月9日 Monochamber Mills 2 Ball charges Composition Calculator for 2 Chambers Mills 3 Ball charges Composition Calculator for 3 Chambers Mills 4 Modification of the Ball Charge after Sampling Analysis Calculator 5 Calculation of the Top Size Grinding Media 6 Ball Charges analysis calculator Weight and Surface of the Grinding Charges 7 Ball Training Courses based on the Grinding Software2016年10月5日 1 Introduction Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent years, the production EnergyEfficient Technologies in Cement GrindingCement Ball Mill Grinding Media wildcer cement ball mill grinding media – Grinding Mill China cement ball mill grinding media composition Request for feedback for a Two Chamber Cement Mill Ball Charge and Jun 15, 2011 I am looking to get feedback for the following cement mill for a white cementgrinding media ratio in cement mill KOOKS

cement ball mill grinding media chargingHXJQ Crusher

2021年11月9日 Mar 16, 2017 cement mill ball mill all calculation cement boll mill grinding media calculation,cement finish grinding mill ball mir shabbir ahmad apr 29 2013 here is the method for correct calculation of cement mill ball charge step 1 draw the cross section of cement ball mill separator efficiency calculation,dynamic air separator

刚玉悬辊矿石磨粉机

--每小时产1800T建筑用高岭土灰石制粉

--石粉厂采样桶

--煅后焦磨粉设备价格

--白泥石灰石粉碎机械多少钱一台

--辽源菱镁矿磨粉机规格型号

--成都高钙粉场

--石灰石碳酸钙磨粉机安全操作规程

--山东雷蒙磨球磨粉碎设备厂家

--生产膨润土深加工设备价格

--石膏重钙粉矿石磨粉机

--砖块矿石磨粉机官方版

--有关方解石磨粉机厂家

--压碎值价格岩石抗压

--热解炭黑室样品粉碎机

--石墨制粉设备投资成本

--制高钙粉机器换筛子

--生产石灰膏需要什么设备

--广东连州方解石雷蒙磨粉机生产线

--浙江重质碳酸钙悬辊磨生产厂家

--浙江磨粉机生产线浙江磨粉机生产线浙江磨粉机生产线

--煤炭行业矿石磨粉机几年折全新煤炭行业矿石磨粉机几年折全新煤炭行业矿石磨粉机几年折全新

--LM立式辊磨机粉磨生产线液压站

--洛阳zenith研究院

--贵州毕节硅石加工粉磨设备

--h4800粉磨生产线

--海边石场

--辊式粉磨系统矿石磨粉机图片

--zl325矿石磨粉机的各项指标

--hb30岩石磨粉机

--