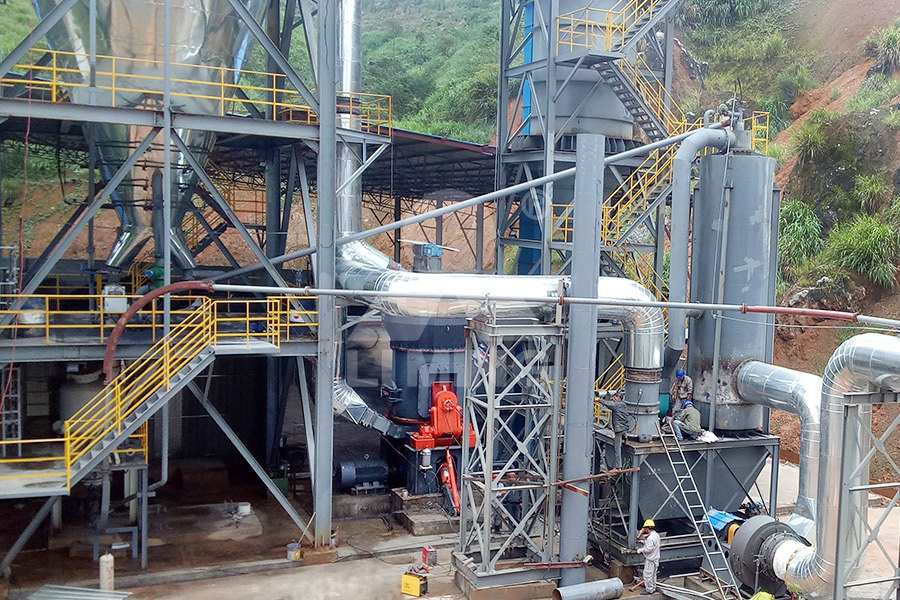

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

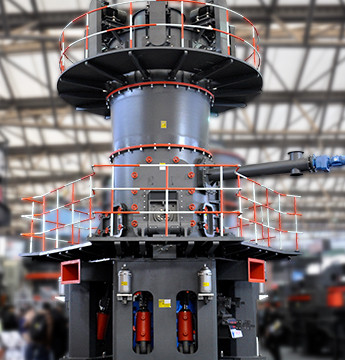

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Quarry Blasting Safety Measures Solution

.jpg)

Quarry Blasting Safe Work Method Statement (SWMS) BlueSafe Solutions

The Quarry Blasting Safe Work Method Statement is a detailed template that comprehensively addresses all safety requirements for operations It is prefilled and ready for immediate use, Fieldscale investigation has revealed that blasting operation at the quarry was performed at three benches with a total of five (IV) blasting sections Table 1 shows number of blastholes, length, Environmental and Safety Accidents Related to Blasting 2024年9月4日 In this guide, we will explore the importance of blasting, the methods used, safety measures, and innovations in blasting techniques What is Quarry Blasting? Quarry blasting involves the controlled use of explosives to What is the Role of Blasting in Quarrying?2015年4月2日 Safety measures in stone quarries are investigated through a questionnaire for safety requirements and the degree of compliance distributed to managers and workers of IMPLEMENTATION OF SAFETY MEASURES IN STONE

1 Prof Dr Nawar Khan, Eng Talib Hussain, IJSER

2023年2月7日 identifying safe blasting parameters for quarry safety management through measuring ground vibrations and study their relationship with quantity of explosives and drilling 2019年10月31日 Almost all quarrying operations have the potential to create dust Control measures should therefore be established to prevent the generation of levels that cause harm These measures should be identified in the health Managing dust risks at quarries Envirotec2011年8月17日 Quality Blasting Audits and Risk Assessments – targeted at highlighting opportunities for cost efficiencies, safety and environmental improvements and blast optimisationQuarry Orica Mining Services2023年3月20日 Safe and eficient blasting requires all quarry and mine operators and supervisors to understand and follow correct procedures for handling and using explosives Operational safety for mining and quarrying Telarc

.jpg)

Drilling Blasting Safety Guidance QNJAC

Safety guidance for those working in Drilling Blasting within the quarry industry2024年7月25日 Site managers must develop and enforce strict blasting protocols—including detailed blast designs, proper handling of explosives, and coordination with all relevant Promoting Worker Safety in Quarries: 8 Practical Tips for 2023年2月7日 Widely accepted limit for residences near construction and quarry blasting (USBM 656, RI 8507) 137mm/s (54 in/s) Minor damage to the average house subjected to quarry 1 Prof Dr Nawar Khan, Eng Talib Hussain, IJSER2023年12月13日 Safety Precautions While Blasting Here are the key safety considerations BICs and blasting crews should consider while shooting the blast: A red flag will mark the blast area for everyone’s safety Evacuate all Blasting Safety: Avoiding Blasting Disasters

Promoting Worker Safety in Quarries: 8 Practical Tips for

2024年7月25日 Ensuring work site safety is essential for safeguarding the lives of quarry workers As a site manager, you must implement robust safety measures like the ones 2024年6月14日 Other researchers opined that those selecting of control measures should consider the quarry’s layout, the types of processes involved, and the quarry’s operating Critical assessment of the effectiveness of different dust Safety Precautions while Blasting For the safety of workers, red flags shall be prominently displayed around the area where blasting operations are to be carried out All the workers at How to Conduct Blasting Operations Safely? [PDF]2009年2月1日 Such ?direct? measures can make it much easier for neighbours and regulators to understand the true effects of blasting on structures and are an important risk control Managing vibration and airblast issues Quarry

.jpg)

Quarry Orica Mining Services

2011年8月17日 Key Benefits for Quarry blasting • Vibration control • Improved blasting efficiency • Enhanced safety and security • Reduced and simplified inventory The Uni tronic™ Electronic 2005年11月24日 part of a railway system that a quarry operates itself forms part of the quarry PART II SAFETY AND HEALTH MANAGEMENT 2 THE PERSON ENTITLED TO WORK Draft Safe Quarry Guidelines to the Safety, Health and 2021年11月13日 Regulation 7 The health and safety document 22 Contents of health and safety document 24 Implementation 25 Provision of information 25 Regulation 8 Management Health and safety at quarries safequarry2023年9月12日 measurement readings in bench blasting The solution of the optimum plan view can have more than one option to choose, since it is dependent on topography, site geology, QUARRY EVALUATION AND CONTROL OF BENCH

Hightech solutions in quarry design and

2020年9月22日 One Central Queensland quarry receives a 3D model of its current pit, benches, broken rock stocks and processed stockpiles monthly The volume measurement of the broken rock stock allows the quarry to estimate 2024年11月17日 Orica’s range of solutions for wall control blasting enables steeper walls and faster vertical advance in cutbacks; reducing the stripping ratio, bringing forward revenue and Quarrying Solutions OricaThe conventional blasting rock excavation method is the main means of rock breakage because of its high productivity, and it is relatively inexpensive compared to other methods However, it raises safety concerns and can A review of some nonexplosive alternative 2022年2月14日 Blasting is a common technique for rock breakage in the numerous civil and mining engineering activities such as excavation, leveling, and tunneling However, this A parametric study of ground vibration induced by quarry blasting

.jpg)

Planning for vibration when blasting Pit Quarry

2024年1月22日 While most of the energy from a blast goes toward breaking rock, some of it travels away from the blast site through the ground and airwaves, according to 2024年8月9日 Rock slope failures pose significant challenges in geotechnical engineering due to the intricate nature of rock masses, discontinuities, and various destabilizing factors during Rock slope stability analysis of a limestone quarry in a case 3GSM products decarbonize quarry blasting and increase productivity and safety in rock engineering including tunnelling by highend computer vision software for rock mass Simply Measure!2019年2月8日 A common problem for quarrying engineers and consultants is the critical challenge of achieving proper blasting Many of the problems faced come from operational To the power of six: Promoting a teamoriented approach to drilling

.jpg)

PQ University Lesson 4: Drilling Blasting Pit Quarry

2019年8月28日 The initial production steps in a quarry operation – drilling and blasting – can significantly impact the productivity and costs of most downstream operations, including 2008年2月1日 Programmable electronic delay detonators have been available for several years from explosives companies The takeup rate of this innovative technology has been high in Benefits of Electronic Delay Detonators Quarry2015年3月6日 Safe blasting practice When Quarry asked Stuart Thomson, Orica’s customer solutions manager for the AustraliaPacific region, what quarry operators should consider when planning blasts, he agreed that the use of Blast incident highlights importance of planning2023年12月29日 Blasting quarry operations are a visual disamenity, and, in proximity to sensitive land uses such as settlement areas or rural clusters, have the potential to not only BLASTING QUARRY OPERATIONS: LAND USE

.jpg)

INCORPORATING MEASURES TO REDUCE GROUND VIBRATION PRODUCED BY BLASTING

2020年6月25日 incorporating measures to reduce ground vibration produced by blasting for quarry safety management: a case study June 2020 International Journal of Scientific and 2024年8月9日 A measurement campaign carried out by an expert in environmental nuisances around a quarry showed that people living in the area were impacted by vibration and blasting Quarries activities monitoring Micromega Dynamics2024年8月27日 The Quarry Safety Partnership is a Tripartite Committee with the mission of promoting, developing and encouraging safety and health in the Quarrying and Construction Safe Quarry A Guide for Quarry Workers Health and 2019年4月3日 Therefor, this product is not technically an explosive until it reaches its final destination, the borehole This allows for a safer and more secure storage and transport of the Dust Control Systems McCallum Rock Drilling

Methodology for measuring the seismic effects generated by quarry

2022年12月20日 The evaluation of the seismic effect can be done by monitoring some parameters that characterize the seismic waves produced by quarry blasting such as: 2021年2月27日 The method used to measure ground vibration is dependent on the blasting application and the type of data that need to be collected Velocity is the most common (PDF) Research of the Technical Seismicity Due to Blasting 2017年10月30日 Fig 4: The input data of bench blasting for the large limestone quarry and its output resu lts Fig 5: A recommended graph for the normal case of bench blasting to design (PDF) Quarry Evaluation and Control of Bench Blasting2020年1月31日 The use of technology such as visualisation and drones is improving the efficiency and safety of blasting operations at quarry sites etc; operational implemented Digitising the blasting process Aggregates Business

1 Prof Dr Nawar Khan, Eng Talib Hussain, IJSER

2023年2月7日 Widely accepted limit for residences near construction and quarry blasting (USBM 656, RI 8507) 137mm/s (54 in/s) Minor damage to the average house subjected to quarry 2023年12月13日 Safety Precautions While Blasting Here are the key safety considerations BICs and blasting crews should consider while shooting the blast: A red flag will mark the blast area for everyone’s safety Evacuate all Blasting Safety: Avoiding Blasting Disasters2024年7月25日 Ensuring work site safety is essential for safeguarding the lives of quarry workers As a site manager, you must implement robust safety measures like the ones Promoting Worker Safety in Quarries: 8 Practical Tips for 2024年6月14日 Other researchers opined that those selecting of control measures should consider the quarry’s layout, the types of processes involved, and the quarry’s operating Critical assessment of the effectiveness of different dust

How to Conduct Blasting Operations Safely? [PDF]

Safety Precautions while Blasting For the safety of workers, red flags shall be prominently displayed around the area where blasting operations are to be carried out All the workers at 2009年2月1日 Such ?direct? measures can make it much easier for neighbours and regulators to understand the true effects of blasting on structures and are an important risk control Managing vibration and airblast issues Quarry2011年8月17日 Key Benefits for Quarry blasting • Vibration control • Improved blasting efficiency • Enhanced safety and security • Reduced and simplified inventory The Uni tronic™ Electronic Quarry Orica Mining Services2005年11月24日 part of a railway system that a quarry operates itself forms part of the quarry PART II SAFETY AND HEALTH MANAGEMENT 2 THE PERSON ENTITLED TO WORK Draft Safe Quarry Guidelines to the Safety, Health and

Health and safety at quarries safequarry

2021年11月13日 Regulation 7 The health and safety document 22 Contents of health and safety document 24 Implementation 25 Provision of information 25 Regulation 8 Management 2023年9月12日 measurement readings in bench blasting The solution of the optimum plan view can have more than one option to choose, since it is dependent on topography, site geology, QUARRY EVALUATION AND CONTROL OF BENCH

花岗岩加工

--工业磨粉机厂家矿石磨粉机视频

--磨粉厂申请磨粉厂申请磨粉厂申请

--瑞泰祥 石膏研磨机价格

--时产700吨欧版方解石粉碎设备

--高岭土企业所需设备

--时产65吨中速磨粉机

--文山 石灰石方解石设备

--苏州中速矿石磨粉机

--蛇纹石欧版雷蒙磨机

--往复式环辊磨的振幅指的是什么

--石磨大连哪里有卖的

--涟源市 机械厂雷蒙磨

--薯类淀粉深加工成套设备视频

--厨房电动磨刀仪

--高岭土粉磨设备厂家

--铝矾土矿石磨粉机械工作原理

--河北井陉重钙立式辊磨机价格

--专业粉碎机厂家

--广西生石灰石灰石粉碎机

--比勒和同煤

--欧版粗粉磨

--煤焦油深加工企业

--pd900粉磨生产线

--开矿要办的证

--超细粉碎机工作原理

--钢铁厂废渣铁如何回收利用

--粉碳酸钙制粉设备价格

--液态高炉渣粒化设备液态高炉渣粒化设备液态高炉渣粒化设备

--日产1800方β鳞石英矿石二氧化硅磨粉机

--